Archive Section

© Text and Photos -

Monday 21st March 2016

At exactly 12:30pm, on Monday 21st March 2016, fifteen members met at Three Bridges station and took the short walk through the car park to the brand-

The purpose-

With a now fully operational depot, the new trains are being delivered at a rate of 1-

The Class 700’s are to be a mixture of 12 car and 8 car sets (dependant on route requirements), and are the first trains of any kind in this country to be of that length – and without centre cabs or any interior gangways etc,. Currently they are in plain white livery, with Thameslink branding along the bodywork.

Two sub-

Railway terminology has already crept in, with FLU (full length unit) and RLU (reduced length unit) being used by Siemens and Thameslink staff to easily identify the differing sets.

The depot has a small pool of internal drivers, with mainline drivers currently only working up to the entrance/exit signals on the reception roads. Within the depot complex is a driver simulator facility, which will be used extensively in the driver training programs over the coming months and years. It is expected be a two-

Operationally, the depot is made up of three separate sections:

- The Down Sidings: housing the depot maintenance building and under-

frame cleaning facility. - The Up Sidings: a smaller yard area with wheel lathe facility also.

- Tilgate Sidings: situated between the Up Sidings and the Balfour Beatty yard.

The later is currently used to store Gatwick Express Class 387/2 units prior to being accepted into traffic, and in time, will also house the withdrawn Class 442 ‘5-

A huge metal footbridge spans the entire complex (and the Brighton Mainlines) giving staff easy access between the Up and Down Yards. We were fortunate enough to walk across this structure, from which the vastness of the depot is clear to be seen. The East and West head-

Three Bridges Siemens Depot -

A Class 442 on the up fast line from Brighton passes the new Three Bridges Depot -

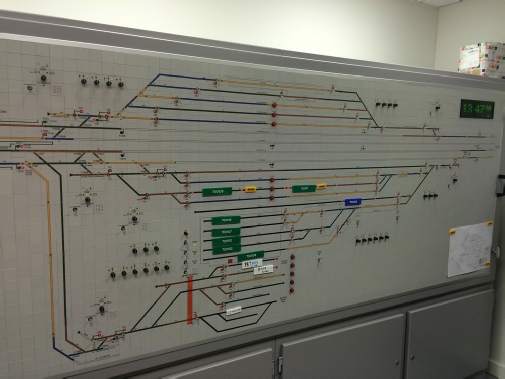

The depot has six access points, two for the Down sidings, three in the Up sidings, and one for Tilgate. The depot has its own internal signalling system, which liaises with ‘Panel 4’ at the Three Bridges Area Signalling Centre in regards to any movements on and off the depot. During our visit, we were given a tour through the control room, and the workings were explained in great detail. The controller has full ability to lock/protect each siding/reception road from his position, and has total control over the fully automatic point-

The Three Bridges Depot NX Signalling Panel

Three Bridges Depot Isolation Panel

The depot current isolation is also controlled from here and individual stabling / maintenance roads can be part isolated giving greater flexibility. To minimise noise (keeping the neighbours happy), sound proof fencing has been erected around the entire perimeter, and furthermore, the train wash unit, under-

At the time of our visit, 9 units were currently in the UK, and all except one were on the depot during our visit. These were: 700109, 700111 & 700002 (located in the Up Yard), 700112, 700107, 700110, 700102 & 700106 (within the maintenance building) and 700108 (which was out on test). Stabled in Tilgate Sidings were Gatwick Express units 387205, 387210, 387211, plus later joined by 387208 and 387209, having worked a 5Z36 test run from Littlehampton.

Class 700 109, a 12 -

The new units are fitted with European Train Control System (ETCS) level 2 cab signallin and Automatic Train Operation (ATO) for use through the central London tunnel sections, where up to 24 trains per hour are expected to operate. Although this system has been used on the Northern Line since 2013, (not to mention several other metro systems around the World), this will be its first use on a UK mainline railway as well as the first use of ATO and ETCS together in the World. The system 'takes over' the controls of the train (once commanded by the driver), and is allegedly better able to regulate its passage -

Class 700 cab.

The combined brake / power controller is to the left of centre on the main desk. The ETCS Driver Machine Interface (DMI) is in the centre which will display a speedometer and when under ETCS Level 2, details of the maximum permitted speed and movement authority distance to go. The screen to the left of the DMI is the train management system display and the two screens on the left are for the external door CCTV images for DOO train despatch. GSM-

The units contain six toilets per twelve coach train (4 for an 8car unit), and a half-

The on-

The onboard systems also have the ability to monitor loading levels within each vehicle and relay this to platforms further ahead, to hopefully, enable passengers to board at lesser crowded coaches throughout the train.

Saying goodbye to our hosts, we returned to the nearby station, with conversation already turning to a repeat visit once the depot is fully stocked with new trains.

Once through the security gates, and safely inside, we were met by Mark Westcott (Network Rail, Signalling Shift Manager), who welcomed us to the Three Bridges Area Signalling Centre.

The centre covers the Brighton mainline from just outside Norbury, right through to the south coast terminus. Additionally, the branches to Caterham & Tattenham Corner, part way towards Oxted, Penge to West Croydon, the Redhill to Tonbridge branch and the lines from Brighton to both Hove and Lewes are all covered from individual workstations. Interface is also made with the depots at Selhurst, Lovers Walk (Brighton) and Three Bridges.

Since 2005, Three Bridges has also been responsible for the Mid-

Opened in June 1983, the Signalling Centre is sadly on borrowed time, as across the opposite side of the mainline formation is the state-

Nine separate workstations are manned at all times, (increased from eight when the busy Norwood Junction -

The actual signalling display panel is a large curved arc shape in the centre of the room, (split into 8 individual workstations), with signallers sitting below their relevant sections with the relevant entry-

L&CI Group Photo in front of 700 109 at Three Bridges Depot

Three Bridge NX Panel

Brighton station on fat left with the Hove station middle of the bottom and the part of the line from Brighton to Lewis at the top.

Brighton Mainline to Preston Park in the centre with the Cliftonville curve to the right of Preston Park station and Haywards Heath station area as a separate section below

Three Bridges NX Panel

East Croydon towards the top left with West Croydon below and Gloucester Road Junction to the right

Following the overview given, we were permitted to roam the floor and take a more in depth look at the operating procedures and talk (if safe to do so) with the individual signallers. Some of the more unusual headcodes and routing details were explained, including the use of Class 9 prefixes for the frequent East London Line trains. Another recent change was to Gatwick Express services, which now terminate at dedicated platforms at the airport station.

The basic concept of 'entry and exit' signalling was demonstrated to our group, as was the process of controlling and monitoring the various CCTV level crossings on the route. The 'approach control' signalling set-

Signal regulation and late-

Whilst observing the Mid-

As our visit was drawing to a close, so the evening peak was starting to take hold. From the relative calm of earlier, the display screens were slowly filling up with plenty of Class 3 and 5 head-

All of this seemed to be taken without issue by the staff on duty – “just another day in Network Rail paradise” it was heard to be called.

As we returned to the station to await our respective trains home, we were on hand to see 700108 passing slowly through the platforms, having that day worked a series of test runs (headcodes 3T24/3T25/3T26) from Three Bridges to Bedford, then to Herne Hill, before doubling back to Blackfriars, and finally returning to Three Bridges.

Thanks must go to our respective hosts at Thameslink and Network Rail for giving up their valuable time, plus to Malcolm Pym and Mike Mundy from the L&CI for their efforts in arranging these visits.