Archive Section

Hongjian Luo

from the Evolution of Modern Traction Seminar on 5th November 2005

1 Introduction

The introduction of electric traction in the late 19th century was to replace the use of steam traction on heavy duty rapid transit suburban railways, underground railways and, subsequently main line railways. Electric traction was found to offer higher energy efficiency, ability to meet increased capacity demands, provision of frequent rail services, environmental friendliness compared to steam traction [Duffy, 2003], higher scheduled speeds and conservation of fuel. [Cock, 1950] From the financial point of view, operating costs for electric traction are lower than steam traction for the same amount of traffic.

The most common methods experimented were Low Voltage Direct Current (LVDC, up to 750 V) with the use of electrified 3rd rails or the use of overhead trolley wire, similar to tram electrification. Through these experiments conducted by various European railways emerged five standard types of electrification systems found across Europe today. They are 750 V DC 3rd rail, 1.5 kV DC, 3 kV DC, 15 kV 16.7Hz AC and 25 kV 50Hz AC.

The Treaty of Rome mandates the European Commission to develop integrated international transport networks which calls for a revival of rail transport for both passengers and freight. The first major step was the implementation of directive 91/440 which requires the opening up of all European national rail networks to all railway undertakings, calls for a separation of infrastructure and operations accounts and implements a system of technical harmonisation removing barriers to cross border rail traffic. The 91/440 directive has since been refined as 2001/12 to legalise open access for international freight on International freight routes by March 2003 and open access for international freight on all EU railways by 2008

However, the technical barriers associated with cross border rail services in Europe today are:

- Five different types of electrification existed in Europe;

- Different operations practices;

- Different maintenance regimes;

- Infrastructure issues, like different track and loading gauges;

- Rolling stock compatibility in terms of loading gauge;

- Train control and safety systems (different signalling systems being used).

The solution for these problems is through the application of directive 96/48/EC in 1996 defined by the EU for ensuring the interoperability of high speed passenger services (TEN networks) between EU countries, and in 2001, the definition of directive 2001/16/EC on the Interoperability of the Trans-

- Without a need to stop at borders;

- Without a need to change locomotive at borders;

- Without a need to change the train crew.

The solution for these problems is through the application of directive 96/48/EC in 1996 defined by the EU for ensuring the interoperability of high speed passenger services (TEN networks) between EU countries, and in 2001, the definition of directive 2001/16/EC on the Interoperability of the Trans-

The directives allow the EU to adopt a transport policy of creating a single market in the rail sector through the definition of various Technical Standards of Interoperability (TSI). [Waboso, D (2004)] The TSI create common specifications and standards to remove technical and operational barriers that work in favour of incumbent companies so that new players can enter the rail industry, thereby promoting competition and the reduction of unit costs through the potential for longer rail journeys for passengers and freight.

The implementation of both directives will improve the competitive position of rail compared to with other modes of transport through greater harmonisation of technical specifications and complement action to liberalise rights of access to the EU network, by making it easier for train operators to operate services across national networks. This enhances competitive pressures leading to higher efficiency and better quality of service to customers. [Waboso, D (2004)]

Since there are five different types of voltages used in European Railways today, the definition of Power TSI 2002/733/EC calls for the standardisation of voltage and frequencies, to allow interoperability of rail traffic on high speed and conventional lines across Europe. The intention is to eliminate the need for multi-

2 Electrification Schemes across Europe

In this chapter the author reviews the various types of electrification systems used on the railways across Europe. The five different types of electrification supplies used across European railways are:

|

Voltage |

Countries |

|

AC 25 kV 50Hz |

UK, France^, Denmark^, Portugal^, Croatia, Serbia, Macedonia, Bosnia, Belgium^, Greece, Finland, Russia^, Spain*, Italy*, Holland*, Hungary, Rumania, Bulgaria, Turkey, Czech Republic^ and Slovakia^ |

|

AC 15 kV 16.7Hz |

Germany, Austria, Switzerland, Sweden, Norway |

|

DC 3 kV |

Spain^, Italy^, Slovenia, Belgium^, Baltic States, Russia^, Poland, Czech Republic^ and Slovakia^ |

|

DC 1.5 kV |

Holland, France^, Ireland |

|

DC 750 V (3rd rail) |

UK |

Key: ^ parts of the network, * High Speed Lines only

Table 1 Electrification Supplies used on European Railways

Source: Kiessling, F, Puschmann, R, Schmieder, A [2001]

2.1 Alternating Current (AC) Electrification

AC motors were invented by Nikola Tesla with the introduction of his prototype induction motor in 1883. In 1904, Siemens experimented with electrification on the branch line from Murnau to Oberammergau in Bavaria, Germany, with AC 15 kV 16Hz using commutator machines. This was the first railway ever to have scheduled passenger operation with AC electrification.

Despite various other experiments conducted by European countries in rail electrification with AC, the first recognised railway electrification with AC was at 15 kV 16.7Hz, single phase supplied by means of Overhead Line Electrification (OHLE). The railways of Austria, Germany, Norway, Sweden and Switzerland adopted 15 kV AC electrification as a standard.

Railway electrification at industrial frequency (50Hz) was introduced by Kando in Hungary between the World Wars, called the Kando system. The electrification supply was at 16 kV AC with 50Hz. The success of this experiment laid the foundation for the decision on electrification policy in Europe after World War 2. [Duffy, M (2003)]

Hence in 1950, this led to the development of the 25 kV 50Hz AC power supply system by both Germany and France. 25 kV AC was found not only to have the advantages over DC in terms of producing higher power with low current but also substantial savings in energy and equipment costs for mainline railways. This development led to 25 kV 50Hz being defined as the standard for mainline railway electrification since in European countries like Finland, Bulgaria, Romania, Denmark and Greece.

Since European railways have been facing intense competition from airlines for mid-

The autotransformer system takes advantage of 2x25 kV AC power transmission while utilising the standard 25 kV AC supply. The autotransformer works on the principal that the train is supplied between +25 kV and rail 0V. The rail and GND currents are returned at 50kV AC to the adjacent transformer. The current on the train is therefore twice the current returning through the autotransformer and the feeder cable. [White, 2003]

As compared to booster transformer arrangements, the autotransformer arrangement:

- Allows an increase in distance between feeder station;

- Reduces losses in distribution and voltage drops;

- Reduces initial costs of providing electrical supply points;

- No need for separate return conductor and booster transformer;

- Allows increased electric train traffic;

- Simple arrangement of contact wire.

With the advantages of autotransformer arrangements in mind, many European high speed railways equipped with 25 kV electrification systems have the autotransformer system installed. They have been or are being installed on the LGV (High Speed Lines in France), WCML (UK), MAV electrified railway lines (Hungary), AVE HSL (Spain), Paris-

2.2 Direct Current (DC) Electrification

The use of DC electrification for the early electrification schemes around Europe in Italy, Belgium, Spain, France, Britain and Holland was influenced strongly by practice in America, mainly by the success of the Chicago and Milwaukee & St Paul high voltage overhead DC electrification scheme. The advantages of using DC on mainline railway were:

- The direct supply of the required power to the DC traction motor, from feeding substations;

- Useful for areas with a lack of the necessary clearances and insulation needed for the installation of high voltage AC systems;

- Simple technology on the train with series-

connected DC motors and resistance control. - There was no need for transformers and rectifiers to be installed, unlike AC rail electrification;

Suitable for multiple-

The drawbacks of DC supply that substations had to be installed at intervals of 8 to 13km to maintain constant DC supply to the lines with the need of heavy suspension equipment to carry the overhead lines and wires with large cross-

DC electrification with OHLE is still used on the mainlines today in Italy, Spain, Belgium; the northern region of both Czech Republic and Slovakia; the western region of the Russian rail network; Slovenia and Poland (3 kV); DSB Copenhagen S-

2.3 Mixed Electrification

There are several European countries which adopted two different types of railway electrification systems on their main lines. The most unique mixed system is in Britain 25 kV AC OHLE and DC 3rd rail (750 V). There are also huge networks of 1.5 kV DC electrification using OHLE in the south of France in parallel with 25kV AC. Countries like the Czech Republic, Belgium, Slovenia and Russia have converted parts of their DC electrification or have electrified non-

2.4 Chapter Conclusions

The implementation of railway electrification in each European country has been guided by a number of factors which include technological advances, the increase in capacity to major railway lines, to cope with an increase in population and growth of settlements, market factors in transport, allow better acceleration and braking, reduction of journey times from A to B, achieve better rolling stock life and its relative economics; and government policies, including those for energy, environment and transport.

3 A Single Rail Electrification across Europe

The European Commission, railway operators, rail infrastructure managers and the rail supply industry have always shared one main objective: making the European railway business more attractive and competitive. [UIC, 2005]

However, without a coherent, modern European railway network, railway operations and especially rail freight will not be able to achieve their full potential on long distance journeys. [UIC, 2005]

The main problems faced by European Railways today are:

- The limits to route and terminal capacity along the most important European rail corridors;

- Different technical standards are still often inhibiting competitive cross border services;

- 10 systems and 16 software variants for control, command and signalling systems;

- Five different types of electrification used.

A joint European-

The use of multi-

But practically, they are more costly to purchase and maintain than single voltage trains, and restrictive in operation due to:

- The implementation of different rules, political issues and regulations by different rail authorities across Europe;

- A challenge in design due to the difficulties in including different types of train control and signalling systems into a train;

- Technical issues regarding voltage ratings under different supplies, reliability, EMC, pantographs and infrastructures;

- Justification of additional costs for additional equipment which is not always in use.

Multi-

Therefore, investing in new infrastructure is another solution to increase capacity through the implementation of a harmonised control, command, signalling [UIC, 2005] and of a standard electrification systems. In the authors opinion, this could achieve:

- Increase capacity and facilitate international operations through improved interoperability;

- Ensuring high levels of safety;

- Reliability;

- Performance;

- Cost effective train operating.

The complexities caused by the current arrangements brought about the question of the need to implement a standard electrification system throughout Europe, based on 25 kV 50Hz AC with standard pantographs, as a solution to both high speed and conventional rail since the issue of common signalling is now being resolved through the implementation of ERTMS.

The reasons for 25 kV being the most suitable choice for electrification is:

- 25 kV is considered a standard electrification adopted by newly electrified mainline railways across the world;

- Allows speeds up to 350km/h with autotransformers, which is currently sufficient to compete with low cost airlines on short and medium distances and with road on longer distances;

- The use of AC 25 kV 50Hz as a standard electrification is the best solution in terms of defining technical parameters. Higher voltages of 50 kV or 100 kV AC are currently not economical,

- Higher voltages are only economical on applications that requires locomotives to draw very high power, like on heavy freight lines;

- The use of 50 kV AC on high speed passenger railway is considered a hazard by Banverket, Sweden;

- The use of 100 kV is only suitable for power transmission from power station to feeder stations, not suitable for railway electrification;

- 50 kV or 100 kV AC electrification requires greater substation spacing where for 100kV electrification, there is a need for 16x spacing for 800 miles. This is excessive and not practical The only such economical operation at high voltages are at remote locations like the Sishen-

Saldanha heavy freight line in South Africa; - As high voltages required fewer substations, which are installed at both ends of the lines in Sishen and Saldanha. This led to easy management of power supply;

- Not required to erect high power transmission lines along the route. [Siemens (1978)] .

The use of DC electrification at voltages higher than 3 kV on high speed lines is not really suitable due to:

- Problems with arcing beyond 3 kV;

- Complex and expensive rectification equipment have to be installed in feeder stations;

- The number of expensive substations to be installed as DC electrification requires shorter substation spacing due to losses.

If the DC supply is capped at 3 kV for high speed lines:

- Very higher currents are required to supply high speed trains with power hungry equipment on board;

- The need for more complex and expensive OHL infrastructures;

- Speed restrictions have to be imposed as higher speeds beyond 220km/h are not encouraged on DC lines presently;

- The wear of the pantograph.

The electrification of high speed lines in Europe with 15 kV 16.7 Hz AC, is not economical due to the requirements to construct new dedicated 15 kV power stations or converter substations.

The ability to use industrial frequency in rail electrification and traction motors today made 25 kV the obvious choice over 15 kV. That is the main reason why Denmark, which borders two neighbouring railways electrified at 15 kV 16.7 Hz AC, chose 25 kV AC as a standard instead.

In the authors view, for operation of high speed and international corridors, 25 kV is the obvious choice. That is the reason why many countries with existing DC electrification like Britain, Italy, Spain, Belgium and Holland are migrating towards 25 kV AC for their new conventional and high speed rail network electrification projects.

3.1 Advantages of a Single System of Railway Electrification across Europe

A standard electrification system based on 25 kV 50Hz AC is beneficial to the European railway network where it could:

- Eliminate interface and complexity issues;

- Possible savings in operational costs;

- Promote traffic growth;

- Improve on the capacities of mixed traffic railways

- Reduce of Pollution.

3.1.1 Eliminate interface and complexity issues.

A standard electrification provides consistency and uniformity in terms of standards for all. Trains can be equipped with simple traction package of transformer rectifier, DC link, converter and AC motors with IGBT control. This removes the complexities in the traction package and at the same time improves reliability, allows the introduction of higher speeds; savings in costs in manufacture and maintenance; and provides savings in time for the journey made.

The use of a single electrification system would encourage innovation, with manufacturers competing with each other in producing faster, more reliable or state of the art locomotives or EMUs, equipped with the latest technology possible with a common standard throughout Europe. It also opens up the possibility of larger production runs and lower unit costs. At the same time, alternatives like Maglev or autonomous traction can be discouraged from being developed.

Common electrification with 25 kV AC could solve problems brought about by trains equipped with the latest technology as noted by Banverket in Sweden. New trains with higher speeds and complex electronics consume more power which has led to the Swedish electrification system at 15 kV 16.7Hz AC encountering significant losses due to its low voltage, low frequency and single phase supply.

This move could pave the way for open access competition on both rolling stock and infrastructure for all European railways. The rolling stock manufacturers and infrastructure companies will benefit as they could gain from orders for new locomotives/EMU, and from necessary modifications of existing locomotives/EMU as many of these industries are downsizing or closing down due to lack of activity. Manufacturers could begin to mass produce trains without any adaptation and modifications needed for operation in different countries.

3.1.2 Savings in operational costs

Through the standardisation of design for trains, prices for purchase or hire of trains will be lower. This in turn lowers ticket prices and operational costs. Compared to diesel trains, electric trains also provide savings in operational cost due to the rising oil prices around the world. This makes diesel traction not feasible in the long run as an alternative for pan-

The introduction of electrification requires the capital cost for an electrification project, which in turn could be earned back over a period of time. Further savings could be made through the use of quality materials with longer lifespan and the reduction of complex on board electrification equipment on the trains. This significantly reduces maintenance costs for both infrastructure and rolling stock.

Time could be saved at borders too with the use of the same type of electrification throughout Europe where the need to change locomotives can take up to a total of 4 hours in some cases. Freight and passenger trains could coast through borders. Savings made in time and operational costs could lead to cheaper rates for the transport of freight and passengers.

Hence, major investments into new infrastructures and rolling stock or upgrading of existing infrastructures and rolling stock remains to be done in all EU countries. The governments of EU nations therefore must be willing to support, invest and have the same vision in creating a standard electrification system for high speed, cross-

3.1.3 Promote growth

A standard electrification system will in turn provide ample opportunities for setting up a high speed passenger and freight market across Europe in response to the competition set by air and road travel for freight traffic.

As reported in 2003, the express freight sector is the fastest growing freight market in Europe, increasing at 5 to 10% annually. [Kuhla (2003)] The development of a single electrification across European Railways could in turn solve the technical obstacles barring the way for the implementation of high speed freight.

In the passenger market, high speed rail could compete with low cost airlines over flights to major cities. The disadvantage of flying is that more time is taken for travelling to/from airports and waiting for the flight than the flight time itself. High speed rail provides a better solution across Europe as it links a city centre to another city centre. Existing high speed network throughout Europe like the Thalys, TGV, ICE or the Eurostar are some examples.

Let us take an example of a direct high speed rail journey between London to Cologne in comparison with flying on a low cost airline. The train journey could be completed in 3 hours, which is less than the time taken to fly on a low cost airline.

A journey by plane could take 4 to 5 hours inclusive of transit between airports, waiting time and delays. The journey from the London to Stanstead Airport takes an hour by rail or more by road transport, with check in, security checks and waiting time taking up another hours. Flight time across to Cologne/Bonn Airport takes about one hour. Upon reaching Cologne/Bonn Airport, it takes about one hour to clear immigration, baggage claim, customs and catching a train into the city.

In the business case, high speed railways operating on a single electrification system could offer competition on ticket prices to low cost airline, whose cheapest tickets are often on flights very early in the morning or late at night and have to be pre-

Disadvantages of using air or road are capacity restrictions in that some European cities imposed bans on night flying, access charging for vehicles into a city or restricted timings where freight vehicles could enter the city. Hence there is a tight schedule for the delivery of goods for commercial or industrial businesses. The use of high speed freight services benefits commercial or industrial businesses in terms of delivery schedules and efficiency.

Another example known to the author was that an economic study by Banverket, Sweden, has shown that the City of Malmo could benefit from a conversion to 25 kV based on the close proximately to the resund link, electrified at 25 kV. A substantial savings could be made through eliminating of up to 10% power of transmission losses and the reduction of maintenance needed for both infrastructure and rolling stock.

3.1.4 Improvements on the capacities of mixed traffic

Capacities of busy mainlines could be increased with a standard type of electrification. This is due to locomotives and EMU could be constructed to standard specification instead of with variable power ratings under different electrification system as shown in table 2.

The differences in power ratings under AC and DC could be eliminated which allows higher speeds to be achieved on mainline in countries previously electrified with DC. The operation of passenger and freight trains at a standard maximum power and speed reduces the time taken travelling on a line and frees up capacity for more trains.

3.1.5 Pollution Issues

According to environmental concerns, the electrification of railways provides a cleaner alternative to road transportation and diesel trains.

The issue of pollution reduces diesel trains or road transport less favourable for long distance freight or passenger services despite its flexibility of movement. This is due to restrictions imposed in environmentally sensitive areas like mountain valleys and major cities. Hence there is a need for high levels of noise reduction and reduction of exhaust emissions from the diesel traction before it could be proven as a worthy competitor to electric traction. [Schmid, 1997]

In terms of maintenance, the cost of maintaining diesel traction is higher compared to multi voltage electric traction. This is because there are more mechanical components that are subject to wear and tear after a period of operation. [Schmid, 1997] The power output of a diesel locomotive is inferior to a multi-

3.2 Disadvantages of a Single Electrification System across Europe

Despite the advantages of minimising complexities on high speed and conventional railways through the introduction of a single electrification, there are disadvantages. They are:

- Financial;

- Justification;

- Bureaucracy issues;

- Economical feasibility;

- Presence of multi-

system locomotives

3.2.1 Funding Difficulties

The biggest obstacle is that the costs required converting all non 25 kV electrification over to 25 kV is prohibitive. This is especially true for countries like Germany who already had significant investments made to existing electrification systems and a change means that a significant investment is needed to implement, which defeats the purpose of the earlier investment. The fragmentation of the railways in some EU countries complicates the issue further as these railways are in private ownership. Private investors would only invest in huge projects on the condition that the project is profitable and offering a return over a short period of time.

It is very difficult for each individual country to manage such projects on their own means without external financial support. Obtaining financial support from the respective governments for a European wide project will be limited because local politicians, who safeguard their own countrys interests, will not see the benefits of high speed or conventional international trains operating into their country. There must be a business case to justifying the investment to all parties concerned, from the railway infrastructure managers (on fragmented railways) or the rail authority to the local government, the State, the national parliament and the European Parliament before funding on any major rail project could be provided.

Since there are many parties to be involved, there will be many politicians who have no knowledge of the benefits of implementing such projects who will strongly object to it. Hence the only possibility of securing funding for a major rail project is through the availability of a low-

The author, however, believes that since the EU is responsible for the definition of the directives, they should be responsible for the provision of funding to major rail projects related to the directives, to each member state and provide support throughout the implementation of the project.

The mentality of the politicians on the reduction of funding to the railways would not change unless the EU steps in with some financial incentives to countries that are willing to promote interoperability of railways. That could convince these politicians to encourage the opening up of their borders to international high speed or conventional rail traffic.

3.2.2 Bureaucracy issues

In terms of response to the implementation of a standard electrification across Europe, the EU and nations using 25 kV electrification will strongly support it but countries with other electrification systems will oppose such a move. There are no common understandings between the EU and member countries on this issue.

The governments of respective EU nations hold the key to any financial inputs to the railway. As each individual country has different financial managements and budgets set aside for its railways, it is very difficult to carry out conversion projects simultaneously according to EU legislation. [Ref A.1 6 Nigel Harris]

This is purely an organisation problem where no politicians see the benefits of rail electrification or proposing financial support to the railway for upgrades. The author has noticed that many governments across Europe are now reducing funding to the railways to support other policies they are committed to, hence forcing the railways to make do with the remainder.

As most railways now require extensive inputs from the private sector to provide maintenance and renewals for its infrastructure and equipment, the expenditure of European railways rises. The railways themselves will not be able to fund any electrification conversion or upgrading work by themselves without the financial assistance from EU or their respective governments.

Bureaucracy issues will be difficult to solve unless the EU becomes a federal union like the United States of America where the federal authority is able to dictate some policies to individual states. Hence decisions on European Rail issues are made by the EU alone in any European wide project implementation, instead of allowing member states to decide what they would like to do themselves after the passing of a new directive.

3.2.3 Uneconomical

An argument from Germany was that if a conversion of the 15 kV 16.7Hz network to 25 kV is to occur; the scale alone is a major obstacle to upgrade just to accept 25 kV. As there are 32257km of 15 kV electrification and at the rate of 1M to install a kilometre of electrification, a total of 32.3bn is required to upgrade the infrastructure alone. The grand total might be around 50-

The existing 15 kV AC system is sufficient for the needs of the railways in those countries. Take the example of Germany where speeds of 350km/h are achievable on ICE services and where 15 kV 16.7Hz supports the huge Rhine-

In addition, 15 kV 16.7 Hz AC is either generated in single-

If countries with DC electrification or other infrastructure enhancements are to be included, the total bill could add up to some trillion Euros which is not economical and not obtain any financial support from the EU or the local governments. A common railway electrification system for Europe is not possible to achieve without the necessary funding to support it. There is no economic reason to justify this funding where multi-

Railways across Europe are downsizing with the focus on international passenger trains declining over the years. Many long distance services are truncated into fragments; hence cross border traffic is not as busy as before.

The economical question also arises on conventional networks that do not link up with each other (for example the Frankfurt S-

The competition from other sectors, like road and air is also intense as they offer better alternatives to rail despite the time taken from origin to destination potentially being longer than by rail. For example, low cost airlines provide more affordable option for passengers and road transport allows freight to be transported door to door across Europe.

The rail passengers are not really concerned about what type of electrification is being used on the railways. They are only interested in getting from origin to destination, concerned with the price for a ticket, punctuality and efficiency of services. The only side effect of electrification to the passenger is the high speed allowed, where 25kV AC electrification allows trains operating at speeds of up to 350km/h which in turn could provide a direct competition to low cost air travel for medium distances.

Diesel is autonomous and could run on all lines, with or without electrification. Most freight operators in certain countries prefer to use powerful diesel locomotives as they could operate from yard to yard without the need for a shunter as if an electric locomotive is used; diesel traction is required for shunting upon arrival at freight yards, which is often non-

There is also the question of equipment and technology where some countries have preferences for cheap implementation, local technology or locally produced equipment than a standard type of equipment used. In the example of the ERTMS signalling system, there are many different suppliers around who could design and install ERTMS equipment despite the specification being the same throughout. Hence, it is just not economical to have a single electrification on European railways.

What is necessary to be done instead is to comply with interoperability requirements within EU countries through the standardisation of technical equipment used on both AC systems. This involves harmonising the different levels of short circuit protection and insulation on 15 kV and 25 kV electrification. The chances of short circuits are higher on 15 kV 16.7 Hz network than on 25 kV therefore require higher protection and the insulation required for 25 kV is higher than 15 kV. Hence the design of the overhead lines, insulation and protection should be key issues to be addressed.

3.2.4 Presence of multi-

The availability of multi-

However, with reference to Chapter 4, all technical and operational barriers in existence that prevent the operation of the multi-

3.3 Chapter Conclusion

The thought of a standard electrification across Europe could be realised theoretically as well as practically; however, this is not justifiable in financial terms as seen by governments and the EU. The investments made to maintain Britains privatised railways alone, as quoted by the SRA, increased 4.3 times since the days of British Rail. The same situation is repeated everywhere across Europe. With the amount of funding poured into the railways increasing yearly due to higher maintaining costs, it is impossible to have any spare funds for new projects.

Despite financial constraints, the author believes that single electrification on European railways is the answer to the challenge posed by low cost airlines or road transport. The benefits are for all to see in terms of freight and passenger traffic. Hence a resolution is needed to overcome the barrier posed by financial constrains and bureaucracy.

4 Conversion Strategy and Further Work

The disadvantages of a common rail electrification conversion outweigh the advantages largely because of the costs involved, as concluded in chapter 5, especially if governments across Europe reportedly cut funding to the railways while costs are rising or, it is difficult to see any funding being set aside for European Railways to standardise electrification for the foreseeable future.

Hence, a resolution is needed to overcome the barriers due to bureaucracy issues presented to existing arrangements for high speed rail and international rail corridors. The reduction of bureaucracy will lead to an increase in rail traffic across Europe, which offers a good opportunity to review and tackle technical issues like standardising of electrification for railways.

4.1 Bureaucracy issues relating to cross border trains

The author has shown that there are bureaucratic issues that affect the efficient operation of high speed rail and international rail corridors. The first issue to be addressed was the need to change locomotives when international trains enter a neighbouring country. The author understands that this was imposed by unions and governments who would like to protect their own railways.

The author believes that there must be new European rules in place for international trains to clarify such issues and to create the necessary agreements during the design phase of locomotives or multiple units for cross border operations to eliminate misunderstandings, like interferences to signalling systems or infrastructure infringements that might arise during the locomotives operation away from their home countries.

The second issue to be reviewed is on the definitions of directives as there are many different styles of management of railways across Europe today. The directives defined do not really provide the necessary guidance but introduce more complexities to European Railways resulting in many different interpretations by different countries.

Therefore this resulted in an EU White Paper on European Transport Policy for 2010 [Anon (2001)], in which it calls for:

- Setting high safety standards for the for the rail network, based on regulations established by an independent body and on clear definition of the responsibilities of each player involved in order to ensure smooth operation of this market in which several operators will share the same stretches of the network;

- Updating the Interoperability Directives to harmonise the technical requirements and provisions on use of all components of the high-

speed and conventional railway networks; - Gradual opening-

up of international passenger services; - Promotion of measures to safeguard the quality of rail services and users' rights;

- Proposal of a directive to lay down the terms of compensation in the event of delays or failure to meet service obligations;

- Development of service quality indicators, terms of contract, transparency of information for passengers and mechanisms for out-

of- court settlement of disputes will also be envisaged; - Creation of a Community structure for safety and interoperability.

The proposal mentioned in the White Paper on European Transport Policy for 2010 is helpful in promoting new solutions to existing issues with European railways. Hence there is a need for member countries to comply with these proposals and to clarify any misunderstandings with the EU.

The issue of finance management have to be addressed too. The author believes that implementation of projects in stages, proper planning and with reference to the lessons learned through mistakes in past projects are the keys to reducing the wastage of finances and time in key projects. Proper project planning in fact led to projects being completed on budget and on time.

Once bureaucratic issues are resolved, the author believes that it will encourage a significant increase in rail traffic across Europe. This will lead to the generation of profits where technical improvements to the railways could be encouraged. The profits earned could be channelled into the technical improvement projects and private investors might be encouraged to invest into the projects.

4.2 Standard Electrification

Once the railways are performing well with the necessary financial supports, there is a need for technical improvements. The author believes that this is the time to review the need for a standard electrification system across Europe. The project could be realised in stages which is cost effective.

On the issue of high costs required for electrification projects, the author believes that the suggested way to tackle finances is through identification of lines that require a standard electrification like High Speed Lines and international rail corridors instead of a wholesale conversion that includes conventional rail

This idea came about after review of the White Paper on European Transport Policy for 2010 and the plans listed by UIC on High Speed and International rail. Based on these reviews, the author suggests a four stage plan to standardise rail electrification across Europe.

4.2.1 Stage 1 Conversion

Part of the first stage towards a standard electrification have already been completed through definitions of European High Speed Lines and international rail corridors like PBKA, Eurotunnel/CTRL, ICE, TGV, AVE, Eurostar Italia networks and HSL Zuid/Oost by EU and UIC. The Majority of these lines have been electrified in line with Power TSI at either 25 kV or 15 kV AC.

These lines are benchmarks to conversion of non 25 kV lines later. The author believes that mistakes made and positive aspects during the planning and implementation stages in these projects could be used as guidelines for future projects. The reduction of mistakes in future planning and implementations could in turn allow the projects to be completed on budget or with cost reductions. This would definitely allow electrification conversion projects to be more economical which would encourage more countries to follow.

4.2.2 Stage 2 Conversion

Second stage conversion is on high speed lines and international rail corridors in countries with DC electrification over to 25 kV AC to be in line with the TSI.

This could be implemented with the isolation of international corridor and high speed trains (25 kV AC) from conventional rail (DC). Similar arrangements have been already implemented in Denmark or Japan where DSB operate S-

Hence, the first step needed in stage 2 is to establish AC electrification in Holland on Betuwe, HSL Oost and HSL Zuid lines. This will signal the start of conversion of DC electrification over to 25 kV AC in Holland.

In parallel, electrification of non-

This could be followed by conversion of DC electrification on international corridors and high speed lines across Belgium to AC. This is because lines in Belgium are already linked to 25 kV AC international rail corridors and High Speed Lines from France, Holland, Germany and Luxembourg. This conversion to AC will encourage an extension of the Eurostar from Brussels into Germany which benefits European rail as a whole due to the rail connections Germany could offer.

4.2.3 Stage 3 Conversion

The third stage would be the conversion of 3 kV DC electrification in Eastern Europe over to 25 kV AC in stages on major international rail corridors in Poland, northern Czech Republic and northern Slovakia, the Baltic States, Slovenia, Ukraine and Russia.

This would be a good opportunity for infrastructure upgrade on life expired electrification systems installed during communist days. A high speed network could also be established in these countries to link up Western Europe with Russia.

The electrification of both the AVE high speed lines in Spain and Eurostar Italia new high speed lines at 25 kV AC are positive steps taken by these countries on Interoperability. While it is not economical to convert the whole of their rail network over to 25 kV, the international corridors like the France-

4.2.4 Stage 4 Conversion

Based on conversations with German engineers at Dresden [Appendix A1] on the issue of 25 kV electrification in countries electrified with 15 kV, the possibilities of conversion are:

- On new high speed lines in which wiring up with the existing 15 kV electrification will cause an overload;

- Huge increase in capacity in which 15 kV is unable to support efficiently;

- The need to replace life expiry 15 kV equipment where it is more economical to upgrade to 25 kV instead;

- Higher speeds than 350km/h, which require the use of 25 kV with auto-

transformer supply. - However, by the time stage 4 is reached, this will be the perfect opportunity to evaluate 15 kV AC network as its equipment might;

- Be life expired and need replacement;

- Problems with overloading;

- There might be the time to replace existing 15 kV rolling stock;

- There might be a need to increase speed of German high speed lines beyond 350km/h;

- The capacity on 15 kV network by that time, depending on the growth of the rail traffic in Europe, might not be able to cope with the demands posed.

Hence, this will be a good opportunity to review the possibility of an upgrade to major international corridor and high speed rail lines in Germany, Austria, Sweden, Norway and Switzerland to 25 kV AC.

From the recommendations above, early conversion of electrification is only necessary in DC electrified countries. This is to be done in stages over a span of 30 to 60 years, only on high speed and international rail corridors; leaving out the existing 15 kV AC electrified countries to be reviewed after the completion of earlier stages and DC conventional rail network which will not be converted.

The author believes that this method of electrification conversion is much more economical and affordable than a complete conversion including conventional rail. In the long run, this method provides sufficient support to an interoperable European rail network that the directives and white paper demand. There is still a role for multi-

4.3 Changeover arrangements

Current electrification changeover arrangements at changeover points require some refinement. This is due to the arrangements now being manual rather than automatic on all situations. As multi-

Improvements could be made at electrification changeover points as technology permits the use of automatic changeover systems which could integrate together with automatic signalling like ERTMS. In this new implementation, multi-

4.3.1 Changeover on the Move

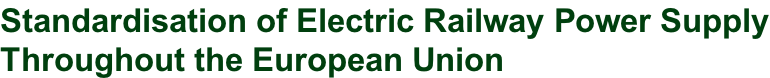

An idea is to use a set of balises to create an automatic changeover system which could be integrated with ERTMS signalling. This system works through the communication of balises between a trains computer system, trackside equipment and control centre and could be used for trains travelling in both directions.

Figure 3 shows a stationary changeover system

Based on the example in Fig 4, the operation for a stationary changeover is simple. Just before the train with 25 kV electrification supply arrives at the stop point of the station, the Euro-

The onboard computer will activate the lowering of the pantograph, switching of the on board electrification to 15 kV AC. Once the Euro-

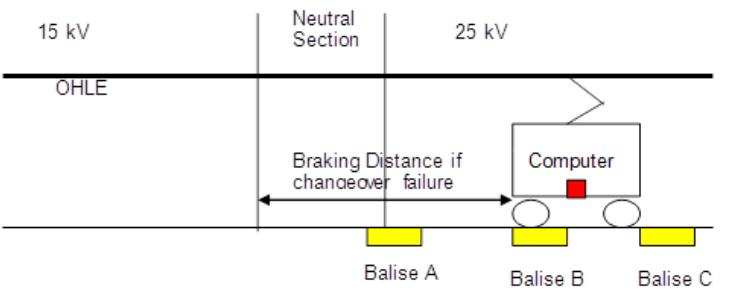

Before the train proceeds, the control will perform a check by GSM-

4.4 A Common Pantograph

Another development in which the author suggests is the development of a standard pantograph head from the current four different sizes into a standard size of 1600mm for all networks with a standard type of contact strip material for AC and DC electrification. This fall in line with the specification in the power TSI section 4.1 where it calls for one type of pantograph collector head to be used on all trains running on future high speed and upgraded railway lines across Europe.

This development allows flexibility of operation of cross border rolling stock as the one pantograph can be used for different voltages with a common specification in tension; stagger, sag and height, for the overhead line thus eliminate the need for many pantographs to be installed on a locomotive.

4.5 Chapter Conclusion

Given the necessary co-

The problems of time wasted for the need to interchange locomotives in Italy, Germany or Czech Republic and the necessary manpower required for changeover mentioned earlier in Chapter 3 and 4, the implementation of automatic changeover system and a common pantograph could be an important solution for time saving and trains joining in or leaving major international and high speed lines which is to be electrified with a standard electrification.

5 Conclusions

The author believed that due to the high costs needed for standardisation of electrification, only major rail corridors defined as Trans European Network and High Speed Lines is necessary for a conversion. This is to be implemented in stages, taking into the consideration on the size of network and renewals of existing infrastructures. An improved changeover system has to be in place for transition between these lines and secondary lines. This could be achieved through implementation of automatic changeover system with ERTMS. Finally, the issue of pantograph size have to be standardised according to TSI 4.1 to 1600mm pantograph head and one type of collector head.

Electrified railways in Europe have come a long way since the early 1900s when various private railways experimented with it as an alternative to steam traction to improve energy efficiency, ability to meet the increased capacity demands, provision of frequent rail services and environmental friendliness. Five standard types of electrification emerged on European railways.

The publication of directives allows the EU to impose a transport policy of creating a single market in the rail sector through the definition of various TSIs to remove technical and operational barriers for railways thereby promoting competition and a reduction of costs through the potential for longer rail journeys for passenger and freight, improve competition with other modes of transport through greater harmonisation of technical specifications and liberalise rights of access for train operators to operate services around the EU. The power TSI calls for the need to harmonise electrification systems across Europe for ease of through operation.

Standardisation of electrification can not be realised at this moment in time due to many bureaucratic issues, uncertainties, complexities in operational issues that the European railways, the Governments of EU states, the EU and UIC have to resolve and agree.

In the issue of finance, the reason for the railways not performing as expected is also due to the bureaucratic issues present. Once these bureaucratic barriers are removed, the railways will be profitable when there is a high demand for European wide rail traffic. The positive result will encourage private investors to invest into the railways as they could see a return in their investments.

Once these barriers have been addressed, steps could be taken to implement the standards as listed in the previous chapter through the review of previous projects, finance management and through proper project planning.

The author therefore believes that all this will lead to the formation of standardised railway electrification throughout Europe on high speed and international rail corridors. This will:

- Promote growth in Pan-

European rail traffic for passengers and freight; - Competitions for other modes of transportation for short to medium distances;

- Encourage trade among European nations and beyond;

- Performance advantages with better acceleration, higher speeds and faster journey times;

- The establishment of high speed and international rail corridors in Europe.

There is an immediate need to improve voltage changeover system on European rail today through the use of automatic changeover systems, which in future could be integrated with ERTMS signalling. This could reduce the time wasted at changeover points for stopping, interchanging of locomotives or changing of electrification systems, which is a barrier to interoperability today.

An improvement to the voltage changeover system will benefit in the long run to interface ERTMS with electrification and act as an interface between high speed/international corridors and conventional rail.

The final issue that could be addressed on standardisation is on the issue of pantographs where different sizes and material currently in use across Europe could be reduced to just two standard types for AC electrification and for DC electrification.

6 References:

Allmr Allmark, P, Luo, H, OMeara, K, Franklin, R, Sivapragasar, R [2004] Change In The Rail Industry Posed by the European Directive on High Speed Interoperability, Change Project Report, Department of Rail Systems Engineering, University of Sheffield.

Anon [2001] White Paper : European transport policy for 2010, Commission of The European Communities, Brussels

Cock, CM [1950] Railway Electrification in Great Britain, Electric Traction Convention 20th March 1950

Directive 2002/733/EC: Technical Specification for Interoperability Relating to the Energy Subsystem of the Trans European High-

Duffy, M. (2003). Electric Railways 1990-

Kuhla, E [2003] Seeking a High Speed Freight Market, Railway Gazette International April 2003, pp 210-

Luo, H [2005] A Common Railway Electrification for Europe, Railway Systems Engineering Department, School of Mechanical Engineering, University of Sheffield

Siemens, W [1978] Will 50kV become a World Standard, Railway Gazette International Aug 1978, pp 201-

Schmid, F [1997] Electric or Diesel: Tilting May Tip the Balance, Railway Gazette International Aug 1997, pp 521-

Waboso, D [2004] Keynote Address to Systems Engineering for the Railway Industry, IEE 26 May 2004

White, R [2003] AC Railway Electrification Supply System, The First Residential Course on Railway Electrification Infrastructure Systems, IEE 2003, pp B4-

Figure 1 shows an Automatic Changeover System (On the Move)

Based on Fig 1 above, the multi-

Once the changeover is performed, this will be indicated (circled) on the information screen on the drivers desk as for current arrangements for multi voltage trains on manual changeover.

Balise B checks with the on board computer system whether a changeover of the electrification has already been performed. If the changeover is already performed, balise B will inform the train of a clear aspect where the train continues its journey, else balise B will activate its service braking and the on board computer will calculate the braking distance immediately and at the same time isolates the on board electrification equipment, lowers the pantograph and advises the driver to perform manual check before activating the new electrification system.

In the events of all balises failed, the control centre will be informed through information sent by the balises and the train driver will be informed of the problem through the cab display or cab radio and will be advised to perform a manual changeover at the neutral section.

An additional fail safe feature that could be implemented is through the use of ERTMS L2 wireless GSM-

Figure 2 shows the implementation of wireless communication to electrification changeover

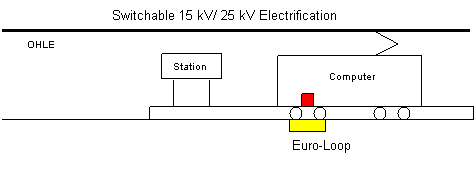

4.3.2 Stationary Changeover

Implementation of an automatic stationary changeover is much simpler, as illustrated in Fig 4. The implementation is identical to changeover on the move but only one balise is used for three operations on triggering, checking and signalling. Another difference is that the OHLE is switchable between both voltages.